How Can You Maximize Storage Efficiency in Your Machinery Shed?

What Factors Influence the Layout of a Machinery Shed?

To make a practical machinery shed, start by checking your equipment’s types, sizes, and how often you use them. Look at the land you have, too. A big thing is giving each machine space to move without hitting others. Plan for room to turn and the size of large farm tools, like combines or sprayers.

The weather where you live makes a difference. Strong winds or lots of snow mean you need tough supports, which can change how you set up the inside. Adding lights or drains also shifts where you place machines to keep work moving well.

Which Types of Machinery Require Special Consideration for Storage?

Each piece of equipment needs its own upkeep. Tractors and harvesters are big and heavy, so they need strong floors and extra ceiling height. Cutting machines like ploughs or seeders need their own space to avoid scratching other equipment or being safety hazards.

Some of the advanced technology needs areas with stable temperatures in which to house sensitive parts, like electronics or hydraulics, from excessive heat or cold. Making separate zones in the shed keeps these machines in good shape.

How Do Aisle Widths and Access Points Affect Daily Operations?

Aisle width changes how easily machines move in and out without delays or accidents. Wide aisles make it simpler to get around but take more space. Narrow aisles save room but can feel tight. Find a balance based on the equipment you use most.

Entrances, like sliding doors or roller shutters, should match your farm’s traffic paths. Integrated Sliding Doors and Roller Shutters for Easy Access let big machines move fast, saving time on busy days.

How Should You Design Your Machinery Shed for Smooth Workflow?

What Is the Ideal Flow of Equipment in and out of the Shed?

A smart flow keeps machines from crossing paths or circling back. Keep equipment you use every day near doors for quick grabs. Put seasonal tools further back. A straight-through layout, with an entrance on one side and an exit on the other, makes work much easier.

This setup cuts down on crowding, especially during busy planting or harvesting days when you’re using lots of machines.

How Can You Minimize Equipment Movement and Downtime?

Grouping tools by how often they’re used reduces extra trips across the shed. For example, keeping tillage equipment in one spot lets workers pick up what they need without extra steps.

Using Built-In Drainage Systems to Maintain Clean Work Environments stops mud or water from piling up around machines. This makes the area safer and saves time cleaning gear before use.

Are There Design Features That Improve Operational Safety?

Safety depends upon open sightlines and easy access. Abundance of light—naturally from skylights or artificially from LEDs—avoids accidents at dawn or dusk. Unobstructed passage ways, strategically placed fire extinguishers, and non-slip floors are added measures.

Heavy-Duty Flooring Solutions to Fit Large Equipment secure floors and eliminate danger from uneven floors under heavy load.

What Materials and Structural Features Enhance Functionality?

Which Roofing and Cladding Options Are Suitable for Machinery Sheds?

Metal cladding is a great choice since it is hardy, easy maintenance, and pest-resistant. Galvanized steel roofing is very resilient to extreme weather conditions and can last for many decades.

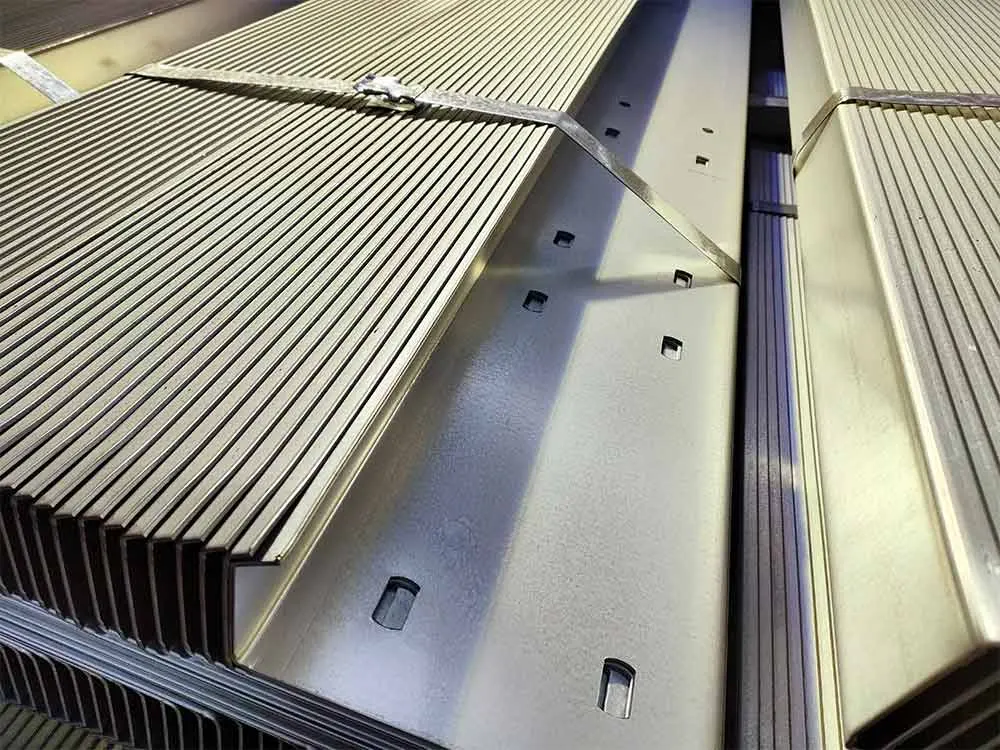

CZT production includes cold-formed steel items like C Types, Z Types, U Types, and Omega Types. These are perfect for building sturdy roofing systems for farm sheds.

How Do Ventilation and Lighting Impact Shed Usability?

Good ventilation prevents moisture, which can rust metal or harm rubber parts. Ridge vents and sidewall louvers let air move naturally, keeping the shed’s temperature even.

Lighting helps with tasks like maintenance or checking machines. Translucent roof panels bring in daylight, cutting down on electric light use and saving energy.

Should You Consider Modular or Expandable Designs?

Choosing modular designs helps you plan for growth, letting you add space as your equipment collection grows without rebuilding everything. This is great for farms that keep adding new tools.

Prefabricated steel parts, like H Steel Beam or Z Steel Channel, make assembly quick and keep structures strong for future additions.

Why Is CZT the Right Choice for Your Machinery Shed Needs?

Who Are We at CZT and What Sets Our Solutions Apart?

Founded in 2013, CZT is based in Tianjin, northern China’s largest port city. We’re a full-service provider for the photovoltaic industry, handling research, production, sales, and project management.

Our skills go beyond solar structures to heavy-duty steel fabrication for things like machinery sheds. Our workshop, with 25 cold-forming lines and 15 punching lines, builds large amounts tailored to each client’s needs.

What Specific Machinery Shed Products Do We Offer at CZT?

Steel-Framed Structures Tailored for Agricultural Equipment

We craft frames with tough materials like Q235B/Q355B carbon steel, ideal for holding tractors, balers, planters, and other heavy gear.

Customizable Bays for Tractors, Harvesters, and Implements

Our modular bays adjust to fit your current equipment, with room to grow using standard parts like C Steel Channel beams.

Integrated Sliding Doors and Roller Shutters for Easy Access

These features make it easy to move big combines or trailers in and out, saving time during peak seasons.

Heavy-Duty Flooring Options to Support Large-Scale Machinery

We offer reinforced concrete slab integration that works with our frames, keeping heavy machines steady in storage.

Built-In Drainage Systems to Maintain Clean Work Environments

Our designs use floor grading and trench drains to handle water, keeping the shed clean and safe.

How Do We Support Our Clients Throughout the Planning Process?

Our global team offers custom solutions for clients worldwide. From first talks to CAD-based designs and final delivery, we handle every detail, so you don’t need multiple suppliers.

With over 2,000 square meters of workshop space, we manage packaging, inspection, pre-assembly, and loading all in one place, ensuring quality from start to finish.

FAQ

Q: Can I customize my machinery shed layout based on my unique equipment?

A: Yes. CZT offers flexible bay setups with modular steel parts tailored to your equipment.

Q: What kind of foundation do I need?

A: It depends on your soil, but we suggest reinforced concrete slabs with our Q235B/Q355B steel frames, available through CZT’s OEM services.

Q: Is future expansion possible?

A: Yes. Our modular designs let you add bays easily without changing existing structures.

Q: Do you offer international shipping?

A: Yes. Our global team provides tailored solutions for customers worldwide.

Q: How long does it take from order placement to delivery?

A: Delivery times vary by order size but usually take 7 to 20 days per component, based on our factory’s capacity.